-

One generator, any fuel. Fuel-flexible power is the route forward.

-

The GS-300 early-entry soft cut concrete saw will be on display as part of our range of self-propelled models at Plantworx.

-

Coma along and take a look at our range of powerful 36" and 46" ride-on trowels with a choice of four or five blades per rotary arm. Make concrete finishing across large slabs and bays a simple task w ...

-

As one of the largest earthmoving attachment suppliers across the globe, the team at Miller is geared up to showcase its array of couplers and buckets at Plantworx 2025.

-

As the industry continues to move toward quieter, cleaner, and more efficient solutions, Brendon continues to innovate with products that combine power, reliability, and convenience.The BBW30KLi is pe ...

-

Prolectric annually saves Kier A417 Project £638,180 in diesel and 833,689 kgs of CO2e using solar lighting, solar hybrid generators and BESS

-

This battery powered 30" (sku SC30E) edging trowel from Speedcrete is used predominately for indoor work but also can be used outdoors.With battery powered trowels there are no fumes making this the p ...

-

The Triple Roller places and finishes concrete by running along form, this machine is specifically designed for accurate efficiently and is suitable for PQ concrete. Operated via a stand-on control pl ...

-

David joins us with a distinguished career history in the construction and engineering sectors. Most recently, he served as Business Development Director with Seddon Plant & Engineers, a fellow member ...

-

Kubota, a renowned leader in the construction industry, is now making bold strides forward with a groundbreaking innovation in electric excavator design.

-

Kubota (UK) will deliver an impressive showcase of its rapidly expanding product line-up at this year’s PlantWorx exhibition, at the Newark Showground,on September 23-25. With one of the biggest stand ...

-

Kubota Corporation has reached an agreement with Sumitomo Construction Machinery to receive an OEM supply of 14-ton hydraulic excavators for the European market.

-

Kubota unveils the brand new U17-5, the latest in the U17 series of mini diggers, redefining excellence in the 1.5-tonne, zero tail swing range

-

Volumech will be attending the PlantWorx live construction equipment event at Newark Showground next

-

From humble beginnings to a world-class leader, Kubota’s journey in excavator production began in 1974 with the KH1, the company’s first mini excavator. This groundbreaking machine set a new standard ...

-

Kubota (UK) Ltd has introduced a digital marketplace for customers, to streamline ordering of genuine parts using mobile or desktop devices. It is called Terrako, and enables Kubota parts to be ordere ...

-

Prolectric the off-grid renewable power and lighting specialist, has introduced ProCharge - a groundbreaking new Three Phase Solar Battery Energy Storage System (BESS), boasting an impressive onboard ...

-

Introducing InTeEx Next-Generation Safety System A cost-effective, user-friendly solution that brings proven railway safety expertise to construction machinery.

-

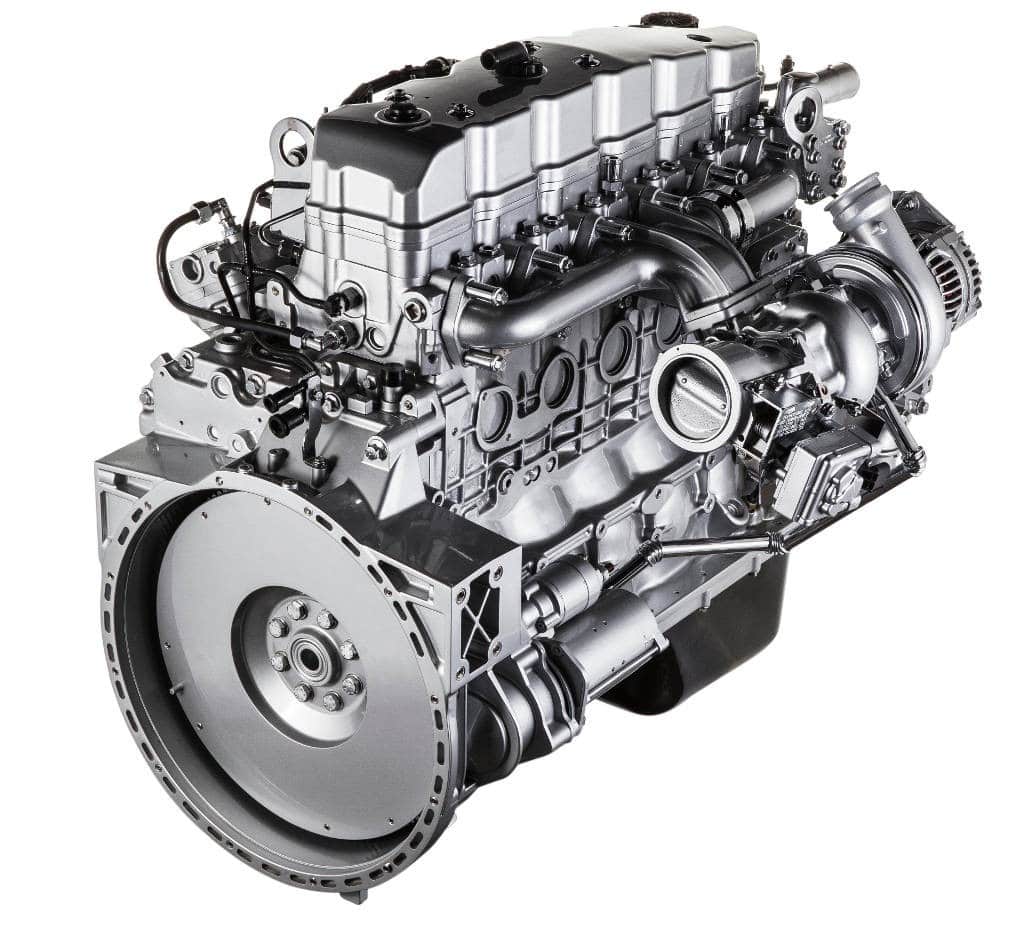

Power Torque Engineering who are the UK distributor for Moteurs Baudouin, a French diesel engine manufacturer, are pleased to reveal the new Baudouin Stage V industrial engine range at Plantworx 2025. ...

-

Known for delivering high-quality consumables, parts, and tools across the UK, HTS Spares continues to push boundaries with solutions tailored to the practical needs of plant operators and maintenance ...

-

The telescopic boom of the YZS2-4 Vanse laser levelling will be on show this year. This laser controlled concrete levelling screed can be operated via a hydraulic control remote control system which a ...

-

VANSE YZS2-4 Concrete Levelling Machine. Total control.

-

Robustrack celebrate a 5th Plantworx show with some top innovation taking centre stage. This year’s stand features the usual favourite hydraulic attachments, including Femac flails and mulchers, Agrif ...

-

According to the Health and Safety Executive (HSE, 2023), 10% of all fatal injuries on UK construction sites are caused by workers being struck by moving vehicles. This statistic puts into perspective ...

-

Launched earlier this year, the MK2 is the first safety system in its category to achieve PLd certification for the civils market—raising the benchmark for operator protection and machine control. The ...

-

TEK Seating, one of the UK’s largest independent vehicle seating distributors for the OEM and aftermarket, is KAB’s nominated distributor for Plantworx.

-

Totalkare is thrilled to announce its inaugural appearance at Plantworx 2025, the UK’s premier live construction equipment exhibition.

-

JCB has launched the VM118D single drum soil compactor, powered by a 55kW Stage V compliant diesel engine engine that requires no Diesel Exhaust Fluid (DEF) to achieve emissions standards.

-

Visit CONTAINEX at PlantWorx 2025 (Stand DD-37) and discover smart, flexible and sustainable mobile space solutions – perfectly tailored to your construction site needs.

-

Among the models on show, professionals will be able to discover the ultra-compact SV08 mini excavator, the SV86-7 and ViO80 midi excavators, as well as the robust C30 tracked dumper – all designed to ...

-

JCB returns to PlantWorx in 2025 with a bumper line-up of machines aimed at the civil engineering, housebuilding, highways and utilities sectors.

-

We're delighted to announce that Chicago Pneumatic will be exhibiting at Plantworx 2025 this coming September!The team is excited to showcase our wide range of innovative tooling solutions, including: ...

-

Global demand for housing is increasing rapidly due to population growth, urban development and rising investment in infrastructure. This growth, combined with labour shortages, is creating a greater ...

-

Con Mech Engineers are returning to PlantWorx with an expanded product range this year, thanks to several strategic distribution agreements with global manufacturers. At this year's stand, the company

-

This move reinforces TVH’s strategic commitment to providing high-quality, certified safety glass to customers worldwide – offering machine operators optimum visibility and protection in even the most ...

-

SHANTUI to Demonstrate Construction Solutions at PlantWorx 2025 SHANTUI, a globally recognized innovator in construction equipment manufacturing, will present its latest technological advancements at ...

-

What sets our new pulverisers apart is their modular design, featuring easily exchangeable wear parts. This new concept allows for unparalleled flexibility, making them suitable for both primary and s ...

-

Hyundai Construction Equipment has developed two new wheel loader safety advances -AAVM+ and Clearview X – as part of its Edition 25 update. These innovative visibility advances improve safety on site ...

-

Hyundai Construction Equipment Europe has unveiled the first two models in the Next Generation of crawler excavators. The 36-tonne HX360L and 40-tonne HX400L are powered by Hyundai’s own award-winning ...

-

BlueJay Solutions is excited to announce its debut at the PlantWorx exhibition, taking place in Newark from 23rd to 25th September 2025.

-

The system provides full visibility of machines, operators and job sites via a real-time, cloud-based dashboard that can be accessed on-site and remotely. Fully compatible with all major OEMs, XW-Insi ...

-

The Connect flatbed is just one of the trailers Brian James will be exhibiting

-

Hydro mounts are advanced vibration and noise isolation components widely used in industrial and machinery applications.These mounts are commonly used due to their high vibration absorption properties

-

Visit stand DB-35 at PlantworX 2025, where Marshall’s Industrial, the official UK & Ireland distributor for HD Hyundai Infracore industrial engines, will proudly showcase the latest addition to the ra ...

-

Hyundai Construction Equipment will have its HW155H hydrogen fuel cell-powered wheeled excavator concept working on the demonstration area throughout this year’s Bauma exhibition in Munich. The pre-pr ...

-

Versatile and reliable, this cutting-edge solution is perfect for a range of applications, from construction and industrial equipment to energy storage devices. Its impressive high energy density not ...

-

Marshall’s Industrial, the official UK & Ireland distributor for HD Hyundai Infracore industrial engines, is exhibiting at PlantworX 2025. Visit us on stand DB-35 to learn more about the super-compact ...

-

Marshall’s Industrial, the official UK & Ireland distributor for HD Hyundai Infracore Industrial Engines, is exhibiting at PlantworX 2025! Visit stand DB-35 to learn more about our range of next -gene ...

-

Experience innovation at its finest with the G2 and DX industrial engine range from HD Hyundai Infracore. These award-winning engines are designed to enhance performance in industrial, commercial, and ...

-

Kubota is excited to unveil the new SVL75-3 compact track loader, a machine engineered to set new standards and versatility for operators across Europe.

-

engcon, the world’s leading manufacturer of tiltrotators, is expanding its global presence by establishing a new sales company in Japan.

-

Reuben Owen's new Channel 5 series, "Reuben: Life in the Dales," has captivated audiences, earning praise as an inspirational figure for young viewers. The first episode features an engaging segment w ...

-

For this year’s exhibition, Plantworx organisers were determined that all aspects of their site setup were as sustainable as possible and that included sourcing welfare that was as low-emission and en ...

-

A leading UK Plant Hire provider Plantforce has announced a new depot opening as part of their Northern depot expansion plan. The new location in Bury, just northeast of Manchester will see Plantforce ...

-

A leading Scottish recycling firm is using a new JCB JS20MH materials handler to process construction and demolition waste. Renfrewshire-based WRC Recycling purchased the machine as part of a major in ...

-

WINGET celebrates its 115th anniversary in 2023 and continues to be a leading and highly respected UK manufacturer of concrete machinery. Founded in 1908, the journey began when British Engineer John ...

-

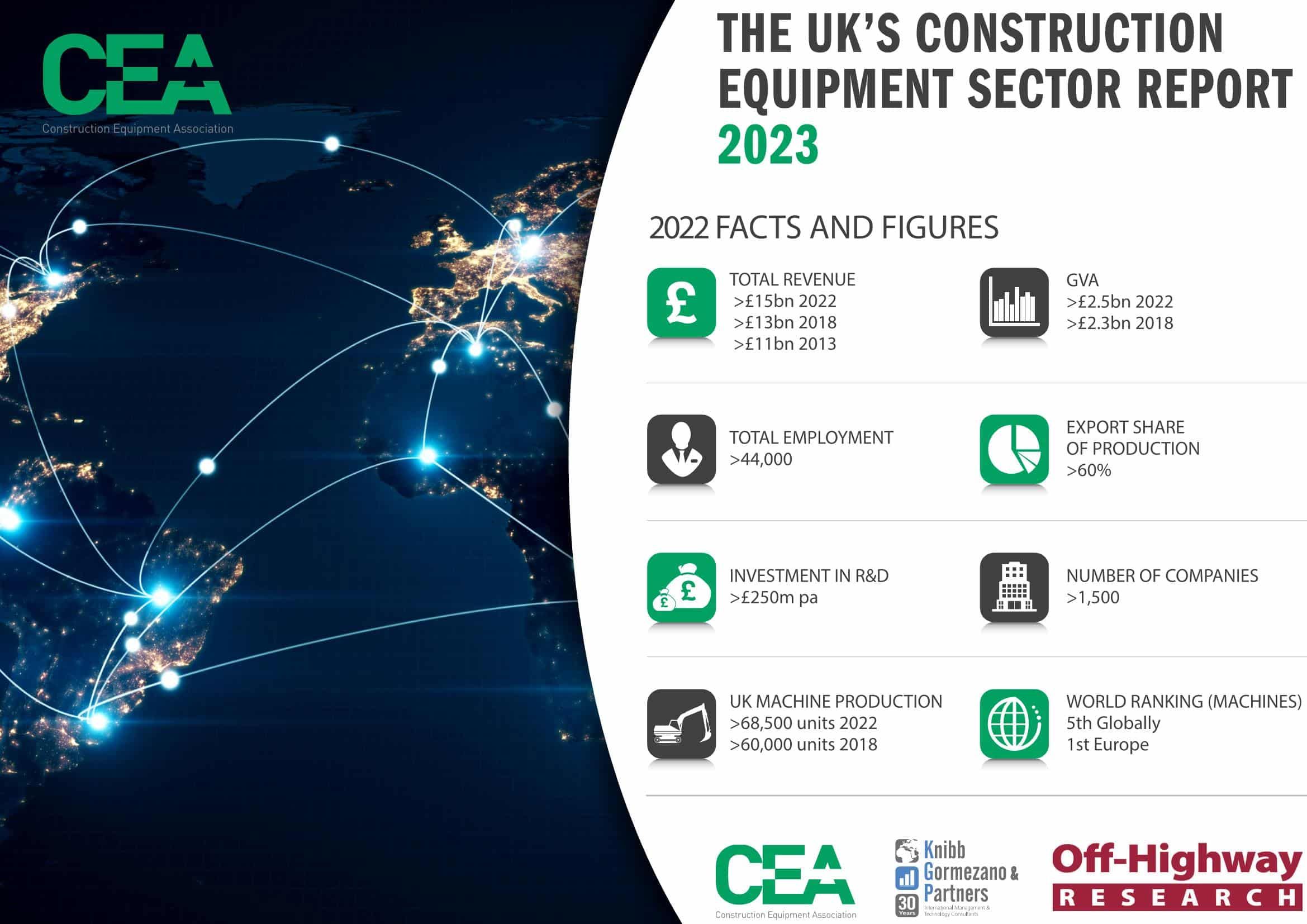

The Construction Equipment Association (CEA) has released the fourth edition of its UK Construction Equipment Sector report for 2023. The report is authored by Knibb Gormezano and partners and contain ...

-

The Plantworx operational team announced today a generous donation of essential household items to Care Zone in Peterborough, in a show of commitment to social responsibility and community solidarity. ...

-

Last week (15th June 2023) at the country's premier plant machinery show, Plantworx in Peterborough, the announcement of CESAR's 600,000th protected machine was made. Suneeta Johal, CEO of show hosts, ...

-

The Best Use of Outdoor Demonstration Award was presented last night at the exhibitor event, following the first day at Plantworx. The category was judged by, Nick Drew (Earthmovers) and Peter Haddoc ...

-

If you are exhibiting Plantworx Construction Exhibition this week (13th - 15th June, East of England Arena Peterborough). You can book an appointment with the National Highways team to show and talk t ...

-

As industry continues to decarbonise, looking to the future, Hydrogen will certainly have its role to play, especially when it comes to the construction sector. This gaseous fuel will be fundamental f ...

-

🌟 Competition - Exciting News! 🌟 Awesome Earthmovers has teamed up with the talented Gaz Evans to bring you a fantastic giveaway! Get ready to be amazed by a stunning scale model of the Hyundai HX22 ...

-

A collaboration between Xwatch Safety Solutions and Leica Geosystems, part of Hexagon, has resulted in the ground-breaking 3D collision avoidance safety solution. This innovation, integrated first by ...

-

Visitors can put the brand-new battery-powered TB20e mini excavator to the test, it will be taking charge of Takeuchi Time, a timed operator challenge where visitors can win daily prizes. The competit ...

-

Advanté, the UK-based manufacturer of the revolutionary Oasis® ‘instant start’ self-contained welfare units, has launched an innovative new Vision Solar toilet block, as part of its commitment to help ...

-

Prepare for an astonishing showcase of talent and proficiency at the All-Level Awesome Earthmovers Operator Challenge, coming to Plantworx 2023! Featuring an inclusive array of operators, from novic ...

-

Part of the Cleveland Group, Cleveland Hire sits alongside one of the UK’s leading suppliers of new and used shipping containers, Cleveland Containers. As the nation’s largest shipping container sales ...

-

New Era, a renowned supplier of fuel, oils, and lubricants, will be exhibiting at the forthcoming Plantworx construction equipment event (13th-15th June East of England Arena Peterborough) The company ...

-

Excavator Forklift is just back from a successful five-day trip to the International Exhibition of Inventions in Geneva. This is an annual hardware, software, engineering, and intellectual property sh ...

-

A new van store inventory solution guarantees vans are always fully stocked ABAX, one of Europe’s leading telematics companies, has announced the launch of ABAX Smart Inventory, a unique van store inv ...

-

Monday 12th June 2023 East of England Events Centre, Peterborough, PE2 6HE Plantworx Innovation Awards Dinner 18.30 – 22.30 The confirmed awards presenter is Shaun Wallace aka the Dark Destroyer quiz ...

-

Advanté, the UK-based manufacturer of the revolutionary Oasis® ‘instant start’ self-contained welfare units which are renowned across UK construction sites, has announced it is the Global Silver Winne ...

-

This year, Elite GSS Ltd will be exhibiting at Plantworx, showcasing, what it describes as, its newest and most innovative non-mechanical plant and equipment for the construction, civil engineering, e ...

-

Plantworx is delighted to announce further National Highways and Costain's representation at Plantworx 2023, the UK's largest working construction event. Key members from the National Highways' Connec ...

-

HJS Emission Technology is excited to announce that it will be exhibiting alongside its UK distribution partner Cybrand AEC Ltd at this year’s Plantworx. Construction emission regulations have been im ...

-

The latest investment from Rototilt®, Rototilt Control, promises better operability, increased energy efficiency and new technology in the cab. The concept, which involves a new tiltrotator series, a ...

-

Concrete Services & Supplies Ltd will be participating in this year’s Plantworx, on Stand B-FD1 at the East of England Arena in Peterborough. Along with a wide range of concreting equipment and machin ...

-

Visitors to Plantworx will be able to learn more about the very latest engines from FPT Industrial with Hendy Power set to showcase the most compact and powerful engines from the FPT Industrial range. ...

-

Unplanned downtime has a significant impact on costs of Construction. Gary Jones, Sales Director of Service Geeni UK, explains the real costs of unplanned downtime and how to minimise it. Downtime Has ...

-

Tiltrotator manufacturer Versaffix is part of the Re-Gen Group and is led by Gerard Doherty and has attained ISO 9001 ‘Quality Management Systems’ certification in its first year. Mr Doherty said: “Ti ...

-

This will be Robustrack’s 4th time exhibiting at the Plantworx event and they have planned its biggest and best show stand to date. With both a static and demonstration area to their plot at DJE2 an ...

-

An initial prototype of an all-new compact wheel loader will be one of many stars featured on Yanmar Compact Equipment EMEA’s exhibition stand at Plantworx 2023. Yanmar Compact Equipment EMEA (Yanmar) ...

-

Plant Parts Ltd, an independent stockist of replacement Final Drives and UK Distributor for FDC (Final Drive Centre), says is proud to announce the release of its latest product line, replacement gear ...

-

South Wales-based machinery dealers EMS Limited will be attending their first-ever Plantworx show in June displaying a variety of equipment from their range of Optimas material handling solutions. Man ...

-

The Plantworx event organisers, faced a major setback when a welfare cabin hire company left their key build-up staff without proper on-site accommodation for the highly anticipated 5th Plantworx Cons ...

-

GAP’s latest specialist divisions – see them in action at Plantworx 2023. GAP Hire Solutions, the UK’s largest independent hire company, will be showcasing its three latest divisions, Trenching & Shor ...

-

MTS Suction Systems are introducing the new MEGA-AIR compressor system option to their market-leading DINO range of suction excavation systems and will be exhibiting the unit mounted to a DINO12 Sucti ...

-

With Plantworx fast approaching, Auger Torque is getting excited. This year Auger Torque is launching three new products; the Cone Crusher Bucket and In-Site Range, as well as the launch of the Kinsho ...

-

NEW – HEAVY LIFT P120.10HM Telescopic Handler Making its debut at Plantworx this year is the new Stage V equipped P120.10HM telescopic handler, bringing new levels of performance in this key heavy lif ...

-

Centre Tank Services will be revealing its newest innovation at this year’s Plantworx exhibition - the Piusi 3000 Supreme. This intelligent running pump will revolutionise the way sites’ fuel is contr ...

-

The Rammer Hammer, known for its outstanding performance, durability, and reliability in challenging conditions, is a coveted prize for anyone in the construction and earthmoving industry. To particip ...

-

Peterborough, UK - Plantworx, the UK's premier showcase of construction machinery and technology, is delighted to invite students of all ages and their families to an exciting and educational day at t ...

-

Plantworx is gearing up for a grand return, and YOU could be one of our lucky prize winners! The gates will swing open next month (13th - 15th June East of England Arena, Peterborough) revealing the l ...

-

DEVELON, formerly known as Doosan Construction Equipment, will be exhibiting for the first time in the UK on Stand B-EB2 & B-EB1 at the Plantworx 2023 Exhibition at the East of England Arena Peterboro ...

-

Plantworx exhibitors have reported instances of fraudulent activity where companies are falsely claiming to be associated with the CEA and Plantworx, the event's organisers. These companies often use ...

-

"EODev's signature 110kVA hydrogen-powered generator, a product of the partnership between UK hydrogen deployment specialist Hydrologiq and French fuel-cell generator manufacturer EODev, will be makin ...

-

The Street King 660 sweeper by Aebi Schmidt is a powerful truck-mounted sweeper designed to efficiently complete a wide range of tasks. It comes with a Volvo 15-tonne LF 4x2 chassis, which allows it t ...

-

Offering a unique way to measure complex spaces, pocket-sized Moasure ONE is making a name for itself as the tool of choice for rapidly calculating the area of indoor and outdoor spaces, and measuring ...

-

As National Highways prepares to exhibit at the upcoming Plantworx Construction Exhibition, Marie Biddulph, Assistant Regional Road Safety Co-ordinator highlights the importance of following regulatio ...

-

Sustainability lies at the heart of Atlas Copco’s presence at Plantworx, with several zero-carbon products on display. During a research project in 2021, Atlas Copco calculated that the majority of em ...

-

Excellent news coming from the UK construction equipment industry. Q1 retail sales of construction and earthmoving equipment have shown strong growth, which is set to create a fantastic atmosphere at ...

-

Brigade Electronics will be attending Plantworx 2023 at East of England Showground, Peterborough, from 13th to 15th June and exhibiting its range of plant and machinery safety systems. Brigade will be ...

-

Ground Stabilisation JJ Mac Ltd is proud to announce the debut of its revolutionary self-loading dumper technology, The Grumper, at Plantworx 2023. The event will take place from the 13th to the 15th ...

-

Get Ready for the All-Level Awesome Earthmovers Operator Challenge at Plantworx 2023! Prepare to be amazed by a remarkable showcase of talent and skill in construction machinery operation at the Aweso ...

-

Sany UK has confirmed its participation in Plantworx 2023. The exhibition is scheduled to take place from June 13th to 15th, 2023, at the East of England Arena and Events Centre in Peterborough. At Pl ...

-

Katie Kelleher has joined the Construction Plant-hire Association (CPA) in the newly created role of CPA Technical and Development Officer. In her new role, she will provide CPA Members with guidance ...

-

The construction industry is no stranger to innovation, and as the sector continues to evolve, social media has become an integral part of sharing knowledge, ideas, and best practices. Plantworx 2023 ...

-

Thomas Group is a well-known group of companies providing a range of services to the construction industry, including plant hire, haulage, tool hire, accommodation, and GPS machine control services. ...

-

Two leading digital solutions companies, MachineMax and PLINX are proud to announce their partnership as co-sponsors of the brand new Get Connected Zone at Plantworx 2023, taking place on June 13-15 a ...

-

An advanced new Vandal Guard cab security system from DIGGER GUARD® provides excellent protection for construction machinery This innovative product is designed to offer a range of exclusive benefits ...

-

For the first time in 2023, Gaz Evans Models (GEMs) will be participating in Plantworx. GEMs specialises in creating top-notch scale models and accessories for the construction, demolition, and recycl ...

-

Takeuchi UK has expanded its new 3-Series excavator range with the new TB350R short-tail swing compact excavator, the company’s first five-tonne class short-tail model. To be launched in the UK at Pla ...

-

Sunward, a world-leading manufacturer of construction equipment and machinery, is set to make its debut at the Plantworx event in the UK this year. The event, which is the only live demo construction ...

-

Avant Tecno, the Finnish compact loader manufacturer, has introduced its new subsidiary, Avant Power, which aims to revolutionise the world of battery technology. The company has produced battery pack ...

-

A new Excavator Forklift attachment has been patented, offering landscapers and small builders a labour-saving solution for their work sites. Designed for use with micro or mini excavators, this attac ...

-

Rotar Engineering has launched a groundbreaking new product, the Fully Integrated Quickcoupler Adapter, designed to overcome the disadvantages of the industry-standard Symmetrical Quick Coupler. The S ...

-

The Cone Crusher Bucket is an original, patent-pending innovation, providing a beneficial environmental impact within the construction. The product will make its debut at the upcoming Plantworx Constr ...

-

Recognising the need for collaboration, big data, automation, decarbonisation and advanced technology in the construction sector, Plantworx 2023 introduces the BIG Ideas Zone. The BIG Ideas Zone is ...

-

SANY is one of the latest OEMs to join the battery-electric drive revolution. Sany will be bringing its SY19E electric mini excavator - to Plantworx 2023 (13th - 15th June 23, East of England Arena Pe ...

-

The UK’s First Suction Excavator with Dual Tipping - see it up close and personal at Plantworx 2023 RSP UK has launched their new and innovative Suction Excavator in the ESE 8 – mounted onto a Mercede ...

-

From June 13th to 15th, 2023, the East of England Arena and Events Centre in Peterborough will be buzzing with excitement as industry leaders, manufacturers, and plant specifiers come together to show ...

-

Datatag the company that Powers the Official CESAR Scheme was challenged yet again by the Industry, Hirers, Utility and Infrastructure companies to try and help combat the Problem of Tool theft utilis ...

-

Plantworx 2023 has announced the shortlist for its 2023 Innovation Awards programme. In this year’s entries, across all of the categories, the focus was very much on environmental solutions, sustaina ...

-

The construction industry has come a long way in the past few decades, and technology has played a significant role in that progress. From machine control to telematics, GPS systems, and safety system ...

-

Leica Geosystems part of Hexagon announce 'game-changing' innovative 3D collision safety solution integration with Xwatch Safety Solutions. Watch the video below and make sure you register to visit P ...

-

Event Postponement – Rail Union Industrial Action Plantworx Innovation Awards Dinner and the CEA Conference has been rescheduled to take place on Monday June 12th 2023 Due to circumstances beyond our ...

-

The 5th biennial construction machinery exhibition is just weeks away – taking place from 13-15 June 2023, at the East of England Arena and Events Centre, Peterborough. Face-to-face business events h ...

-

Retail sales of construction and earthmoving equipment showed further growth in the first month of the year, recording a 10% increase compared with January 2022 levels, as shown in the chart below. Th ...

-

Retail sales of construction and earthmoving equipment continued to show very strong growth at the end of 2022. Sales in Q4 were 20% above the same quarter in 2021, and as a result, sales for the full ...

-

Student Day at Plantworx Construction Exhibition Addressing the Skills Gap Thursday 15 June 8:30am – 4:00pm Pupils, students, and graduates are invited to attend Plantworx on the last day of the event ...

-

Introduction The Simulation Zone at Plantworx, a cutting-edge training platform for construction professionals, is making a triumphant return for 2023 after its incredible debut in 2019. This innovati ...

-

The biennial Plantworx Construction Equipment Exhibition and the CEA have once again teamed up with educational organisation, Primary Engineer, to work with primary schools in the Peterborough area, o ...

-

This is reflected in its recently rebranded Asset and Solutions Division, which is already changing the future delivery of the 500+ project sites it mobilises every year. To find out what the future l ...

-

Merlo is amongst the latest machine distributors in the UK to fit CESAR and Emission Compliance Verification (ECV), to the Merlo range of machinery. The decision to begin fitting CESAR Security and E ...

-

Plantworx exhibitor, Thomas Plant Hire began its journey a quarter of a century ago in 1998 when MD Wyn Thomas founded a contracting business in Holywell in North Wales. The company has since grown in ...

-

Spanning more than 150,000m2 of exhibition space, Plantworx (13th-15th June 23, East of England Events Centre and Arena) will give visitors an opportunity to see some of the latest plant and machinery ...

-

Huge congratulations to the CEE Executive Director, Rob Oliver, on being awarded an MBE in the New Year's Honours List. The Plantworx team is delighted to hear that Rob Oliver, Executive Director of C ...

-

Mark Royse, Head of Sales at Mecalac Construction Equipment UK, discusses with Plantworx why the future of compact equipment design and manufacture will be widely driven by efficiency, productivity an ...

-

Plantworx exhibitor, The MHM Group has seen a sharp rise in demand for sustainable equipment that could save clients nearly three-quarters of Co2 emissions. The MHM Group, a UK-wide distributor of le ...

-

Plantworx exhibitor MachineMax has recently published a whitepaper about the global sustainability challenge the mining industry faces and how data is a key way to tackle this. The global mining indus ...

-

Genquip-Groundhog, a leading manufacturer of sustainable welfare units and temporary accommodation units and a long-term supporter of the Plantworx event, has been given the accolade of a ‘CSR World L ...

-

Retail sales of construction and earthmoving equipment in October were 11% above sales in the same month last year. As a result, sales in the first ten months of the year have almost caught up with la ...

-

It was not so long ago it seemed petrol and diesel-powered industrial machinery would always have the upper hand in the construction sector. Battery-powered machinery was naively regarded as a non-sta ...

-

The 5th biennial construction machinery exhibition will be held on 13-15 June 2023, at the East of England Arena and Events Centre, Peterborough. Technology is changing the face of the Construction la ...

-

It's been a hectic week in the sales office at Plantworx headquarters - Angela has signed up 20 new exhibitors, who have committed to Plantworx and have secured their stands at the 5th biennial constr ...

-

UK Construction equipment sales showed growth in August, which is excellent news and a good sign that the construction equipment sector is moving in the right direction. This rise in machinery sales b ...

-

New features planned for Plantworx 2023 Up to 20% more inside space – with a wider stand choice. Upgraded on-site services – to enhance the exhibitor experience. Big Ideas showcase – tailored promot ...

-

Even though the weather at the last Plantworx event in 2019 was challenging thousands of visitors made the pilgrimage to the event which proved to be a great success. This was thanks in part to its mo ...

-

The 5th biennial construction machinery exhibition will be held on 13-15 June 2023, at the East of England Arena and Events Centre, Peterborough. The CEA is looking forward to hosting Plantworx once a ...

-

The Plantworx 2023 show is going great guns! Angela Spink has been inundated with enquiries and signed booking forms to exhibit at the 2023 event. The layout has been altered for this event so the ‘di ...

-

Another six companies have booked to exhibit at Plantworx this week and a further 16 have reserved their stand pending booking forms. Sales are closed until Tuesday because of the Bank Holiday – but y ...

-

Prolectric, the off-grid, renewable lighting and power specialist, is exhibiting at this year’s Plantworx 2023, at the East of England Arena & Events Centre, Peterborough, 13-15th June, on stand D-LA ...

-

The Street King 660 sweeper by Aebi Schmidt is a powerful truck-mounted sweeper designed to efficiently complete a wide range of tasks. It comes with a Volvo 15-tonne LF 4x2 chassis, which allows it t ...

-

Brigade Electronics will be attending Plantworx 2023 at East of England Showground, Peterborough, from 13th to 15th June and exhibiting its range of plant and machinery safety systems. Brigade will be ...

-

The Tyrefix Group, a leader in plant tyre and machinery repair solutions, is excited to announce its participation in the upcoming PlantWorx 2025 exhibition, taking place at Newark Showground from 23r ...

-

ABAX UK showcases tool and plant tracking at PlantWorx 2025. Trusted by 45,000+ firms across Europe, our tech cuts loss, boosts uptime, and drives smarter, ESG-compliant construction. Stand QD-02.

-

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)